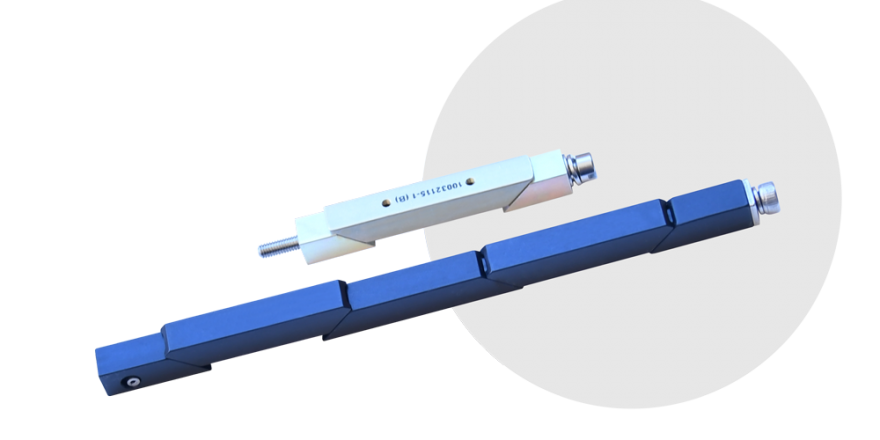

Track Adjuster

Used for adjusting track tension on tracked vehicles, the Track Adjuster is a critical component that needs to be highly reliable to ensure mission success. GES Engineering’s indigenous Track Adjuster is a reliable solution with high strength and sealing.

Purpose

To fulfil its role in a highly reliable manner, the Track Adjuster is required to have excellent sealing. As a hydraulic system, the Track Adjuster is subjected to four to five times the pressure sustained by standard hydraulic systems during the movement of a tracked vehicle over rough terrain.

With its specially-designed seals and the sensitive manufacturing it carries out within very strict tolerance levels, GES Engineering has succeeded in developing a highly reliable Track Adjuster that functions flawlessly, even under high pressure conditions.

Innovative Features

GES Engineering’s Track Adjuster brings numerous innovative features:

- High sealing and reliability

- High resistance to saltwater and corrosion, allowing its use in amphibious vehicles

- Ability to be used on a wide range of vehicles, including the ACV-15, M113, M60 and KAPLAN-10

- Ability to change seals with basic hand tools while in the field

Adaptability

GES Engineering’s Track Adjuster is a passive system. If requested, it can also be adapted to vehicles with active systems.

Potential Projects and Areas of Use

- All tracked vehicles weighing up to 60 tons

Latest Developments

GES Engineering has completed all design and qualification works for its Track Adjuster, and has now started deliveries. Having covered a distance of some 15,000 km on a KAPLAN-10 vehicle, developed by FNSS for the Anti-Tank Vehicles project, and having passed many challenging tests together with the vehicle, the Track Adjuster has already proven its reliability in the field.

Characteristics

General Characteristics- Operating pressure of up to 6,000 psi (800 bar)

- 5 m/s operating speed

- 10,000 km lifespan

- Operating Temperature: -32°C - +49°C

- Compliant with MIL-STD-810G