Fire Suppression System

GES Engineering adds an effective, innovative and reliable solution to its range of fire and explosion suppression systems, which are the last line of defence in ensuring the protection of personnel in military vehicles. GES Engineering’s Fire Suppression System solution, whose electromechanical valves can be tested multiple times, takes reliability, maintainability and field logistics support to the next level.

Components of the Fire Suppression System

Purpose

GES Engineering manufactures Fire Suppression Systems by merging its own engineering knowhow with the 30 years of extensive experience of MARTEC, whose competence in this field is well known by both end users and the sector. The system, which complies with STANAG 4317 Ed.3 standards, ensures the safety of personnel by minimising the effect of explosions caused by rockets and missiles targeting the vehicle and of fires caused by Molotov cocktails and technical faults.

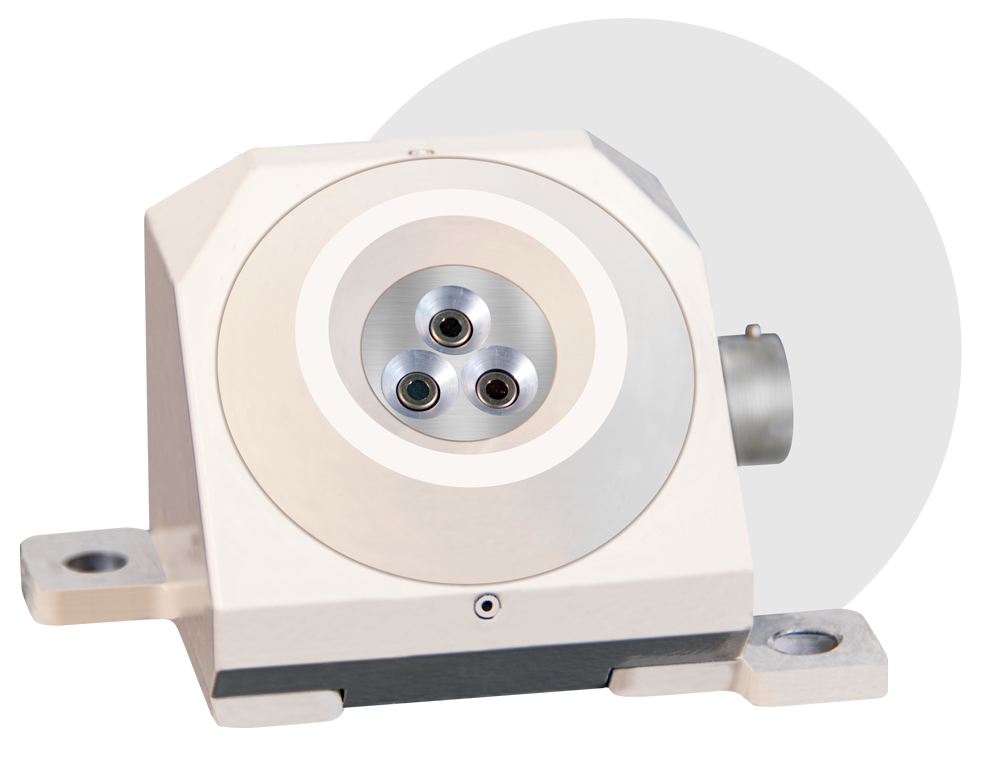

The system combines the use of triple Infrared flame detectors capable of responding in less than 2 ms and quick release high rate discharge valves that enables explosion suppression in less than 250 ms. The opening time of solenoid valves in the system is 7 ms while the discharge time of the tubes is less than 90 ms. Made of aluminium, these components are all in possession of military and pressure vessel certifications.

The extinguishing chemical in the tubes is sprayed directly onto the flame at high pressure at an angle of 120° through the special nozzle at the end of the tube. As a result, the extinguishing effect occurs much faster than with dispersed spraying systems. The detectors are based on Infrared Tri-band technologies, ensuring a rapid response time and advanced false alarm prevention. As such, the detectors are not activated by welding sparks, camera flashes, cigarettes, etc.

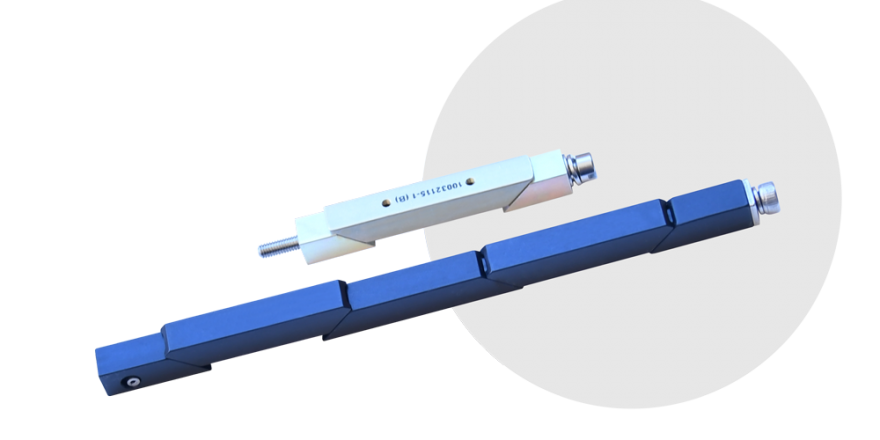

Temperature Detector

Experience

For its Fire Suppression Systems, GES Engineering cooperates with MARTEC, a specialised company in this field. Under this cooperation, the advanced design and production capabilities of GES Engineering are brought together with MARTEC's nearly 30 years of experience in this field. Fire Suppression System was started to be produced in Turkey under MARTEC’s license, after which the indigenous localization rate of the product will be gradually increased.

The Fire Suppression System, which has already entered the inventories of many countries around the world, is used in numerous military land vehicles. Thanks to its proven capabilities aboard those military vehicles engaged in active field operations in a wide range of geographical terrains, the Fire Suppression System continues to be the choice of world armies. The product satisfies the needs of a wide range of users, and based on continuous user feedback from the field, the system is updated every day and equipped with new technologies.

Infrared Detector

Indigenous Production

Under the strategic cooperation agreement signed between GES Engineering and MARTEC, all the assembly and testing of the control unit electronics, as well as the production of electronic cards, will be carried out in Turkey, while the software will be transferred as open code. The production of mechanical parts has started in Turkey, while the filling of the tubes, valve assembly and the testing of the parts will soon be launched. Upon the completion of the indigenisation works, all of these parts will be produced in Turkey by of GES Engineering. In the future, the system software will be able to be modified to meet different requirements.

Testability

GES Engineering's Fire Suppression System operates with electromechanical valves that comply with ISO 17871:2015 standards. Unlike pyrotechnic valves that contain explosives, and therefore cannot be tested, electromechanical valves can be subjected to repeated testing and use.

This feature enables the electromechanical valves to be connected to special test systems and to be fully tested with all their functions, with the activation time measured through the test system. In addition to the valves, all of the other components in the system are also tested before delivery to the customer, guaranteeing that the system will activate when the need arises.

During testing, gas is pumped into the tubes and a full leak test is performed on the electromechanical valves. In the leak tests, the amount of gas leaving the valve is measured using a sensitive measuring device, and any valves not performing to the defined limits are not delivered.

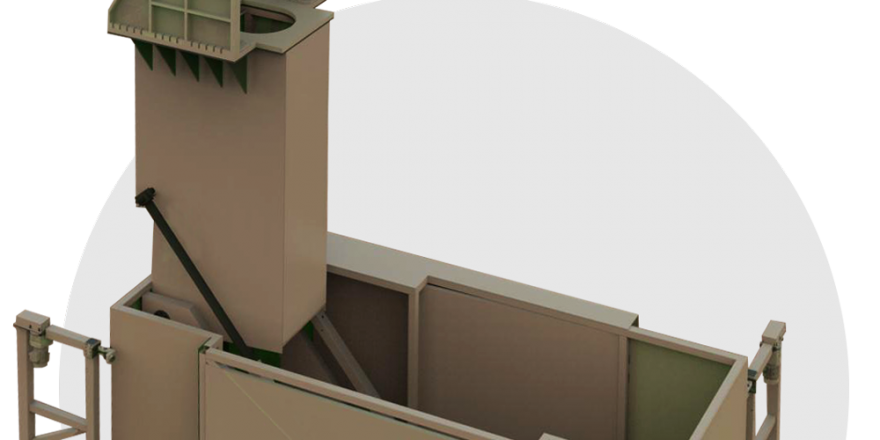

Control Box

Maintainability and Logistics

Since the valves of GES Engineering’s Fire Suppression System are not pyrotechnic, they can be made ready for reuse in a minute. Single-use pyrotechnic valves, on the other hand, must be reworked by specially trained personnel and only by replacing some of their subcomponents. With this feature the Fire Suppression System gives users a product that can be maintained even under field conditions. Furthermore, since the electromechanical valves contain no explosive materials, they do not require special procedures for transportation.

Innovative Features

The innovative features of GES Engineering’s Fire Suppression System are as follows:

- Electromechanical valves that can be fully tested prior to delivery

- Ease of transportability as the system does not contains any explosives

- Multiple-use electromechanical valves

- Ease of maintenance

- The first STANAG 4317 Ed.3 compliant product in Turkey

- Ability to be used in the engine compartment

- Detector glasses that are not affected by dust and smoke

- Modular and scalable structure

- Components that can be configured according to user needs

- Fast and seamless integration process thanks to the company’s advanced engineering capabilities

Extinguisher Tube

Adaptability

Thanks to its modular and scalable structure, GES Engineering’s Fire Suppression System can be integrated into any vehicle, from the smallest to the largest. Following a customer-oriented approach, GES Engineering, unlike many system manufacturers, can configure the Fire Suppression System to respond to all kinds of user demands. The company also offers customers a fast and seamless integration process thanks to its advanced engineering capabilities.

Potential Projects and Areas of Use

The Fire Suppression System can be integrated into all types of land vehicles, including those deployed in areas where there may be a threat of attack that may cause fire, and where there is a fire risk due to overheating related to environmental conditions. The system can also be integrated into military type shelters.

Characteristics

- Detection: Infrared Detectors

- Sealing: IP67

- NATO Compatibility: STANAG 4317 Ed.3

- Resistance to Environmental Conditions: MIL-STD-810

- Detection: < 2 ms

- Opening of Valves: < 7 ms

- Discharge of Tubes: < 90 ms

- Explosion Suppression: < 250 ms

- Number of Controlled Zones: 4

- Number of Detectors: 8 (up to 16 with additional module)

- Number of Extinguisher Tubes: 8