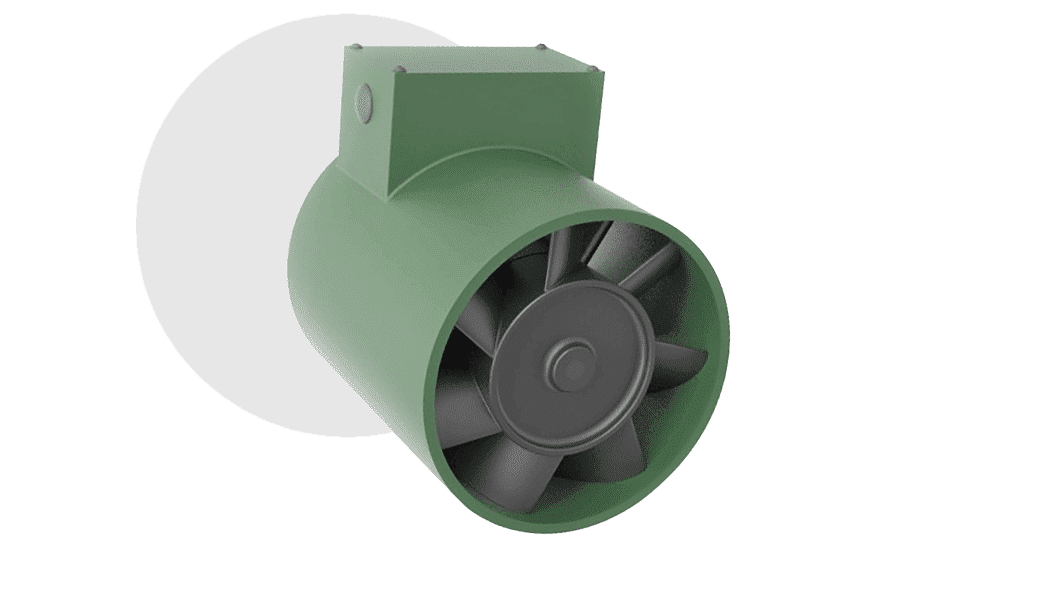

Fans

With the family of fan products it has developed, GES Engineering conveys its capabilities in analysis and production technologies to the fans required by the defence and aerospace sector. GES Engineering develops products with lower power requirements but with a stronger flow. The company’s fan product family currently includes blower and cooling fans.

Purpose

In defence and aerospace, fans used for cooling, air-conditioning or exhaust must satisfy a plethora of challenging and equally conflicting requirements, such as low volume, low power consumption and high flow rate.

. Under these circumstances, the optimal solution can only be found through the use of modern analysis tools and production techniques. Offering an optimal solution through innovative analysis and production approaches, GES Engineering’s blower fans ensure 10 percent more flow with 25 percent less power consumption when compared to equivalent fans on the market.

Innovative Features

GES Engineering’s fan solutions incorporate a number of innovative features:

- Greater flow with lower power consumption thanks to their blade design and production techniques

- Low cost

- Lower noise level

Adaptability

GES Engineering can design fans with dimensions, power consumption levels and flow rates that match user requirements.

Latest Developments

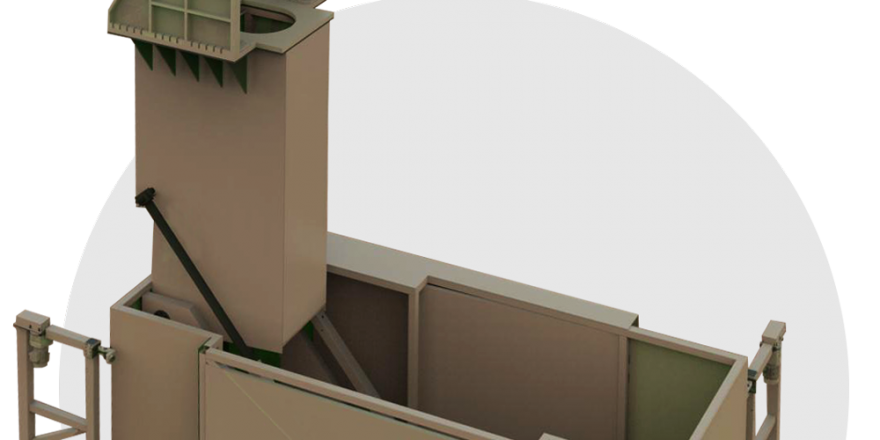

GES Engineering’s blower fans have proven themselves in functional tests observed by FNSS officials. The tests were carried out using modern testing equipment that was also designed by GES Engineering. Qualification works for the fans are currently underway.

Characteristics

- Can be used in any environment or on any vehicle that has cooling or air evacuation needs.

- Evacuate the gases that form in armoured vehicle turrets with the firing of guns and machine guns.

- 400 CFM at zero static pressure

- 5” diameter

- 8,500 rpm with 24 V DC current

- Brushless DC engine

- Operating Temperature: -40°C / +65°C

- IP Level: IP 65

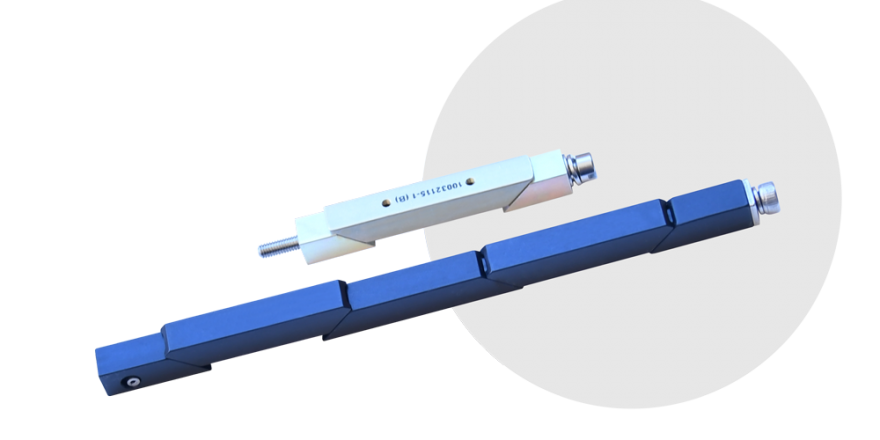

- Used for the cooling of electronic devices.

- 220 CFM at zero static pressure

- 4” diameter

- 5,500 rpm with 24 V DC current

- Brushless DC engine

- Operating Temperature: -40°C / +85°C

- IP Level: IP 65