Automatic Vehicle Leveling System

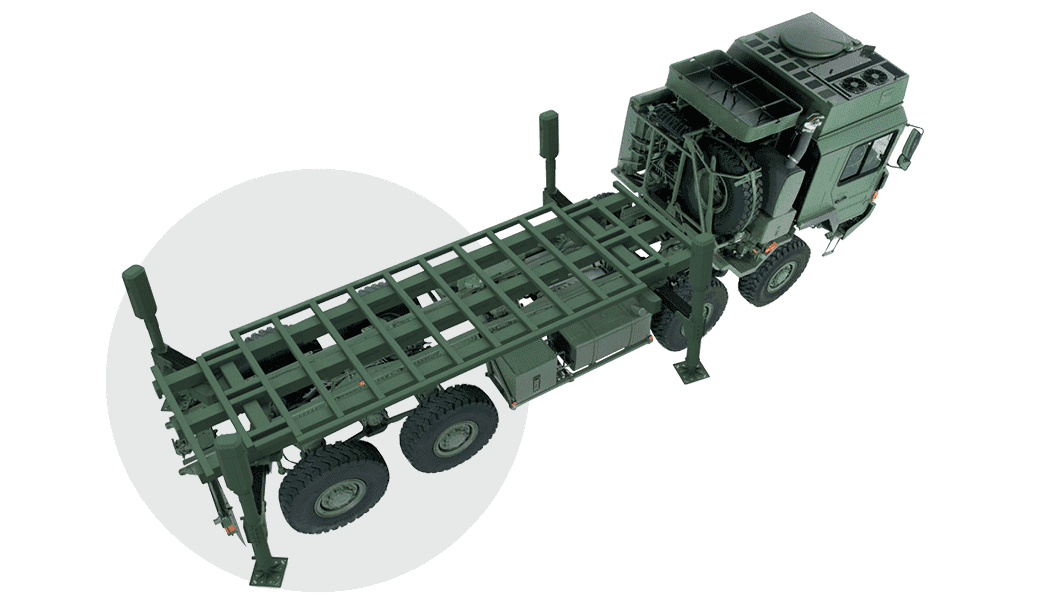

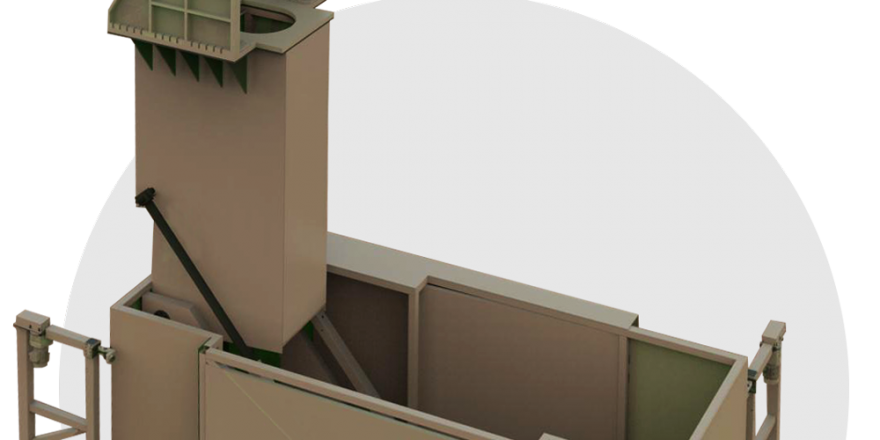

Using vehicle-integrated systems such as radars and launchers when on sloping terrain can be difficult. The four deployable legs of the GES Engineering Automatic Vehicle and Platform Leveling System can level vehicles rapidly and with high precision, allowing the systems to fulfil their tasks to maximum effect.

Purpose

To date, most vehicle-levelling systems have made use of hydraulic solutions, which come with particular disadvantages. For example, changes in ambient temperature can cause leaks in hydraulic systems, and such leaks can, over the course of hours, days or weeks, gradually affect the levelling of a vehicle installed with such a system. Repairing these hydraulic systems in the field is all but impossible.

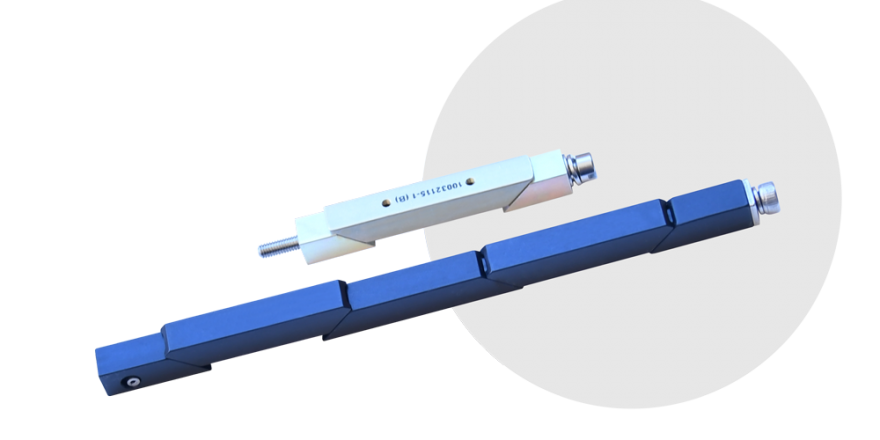

Electromechanical solutions, among which can be counted GES Engineering’s Automatic Vehicle and Platform Leveling System, activates a break mechanism in each leg after the vehicle has been levelled, ensuring that the vehicle stays level for the duration of its mission.

The system is fully automatic, which allows the leveling processes to be completed within a much shorter period of time. The Automatic Vehicle and Platform Leveling System can level a vehicle of 40 tons in less than four minutes, with a precision of 0.2 degrees. In non-automatic systems, the time required for the crew of the vehicle to complete this task using a water/spirit level depends on their level of skill, and can take around an hour.

Innovative Features

GES Engineering’s Automatic Vehicle and Platform Leveling System comes with numerous innovative features:

- Automatic levelling performed within a minimum amount of time

- Level maintained throughout the mission duration, with zero loss of angle

- Minimum maintenance requirements and ability to be repaired and maintained in the field

- Side-deployed legs

- Four metre spacing between legs that enables easy use of payloads such as radars

- Remote controllable

Latest Developments

GES Engineering launched works on the Automatic Vehicle and Platform Leveling System in the last quarter of 2016 after receiving a purchase order from ASELSAN. Following the analysis and design works, the system started undergoing functional tests in the last quarter of 2017. Qualification of the system was completed in the last quarter of 2018, and the system is now ready for deliveries.

The system can be adapted for vehicles weighing above or below 40 tons, and can thus be used with a broad spectrum of vehicles, ranging from 4x4 vehicles to large vehicles such as missile launchers.

Potential Projects and Areas of Use

- Military Radar Systems

- Missile/Rocket Launching Vehicles

- Military cranes

- Mobile Control Stations

Characteristics

- 40-ton load capacity

- Ability to operate under winds of 120 km/h

- PLC-controlled automatic system

- Automatic detection of gradient and angle of elevation

- Legs deployed up to a distance of 750 mm

- Legs elevated up to a height of 1,200 mm

- Levelling can be performed on gradients of 3.5 degrees, and to an angle of inclination of 5 degrees.

- Levelling performed under four minutes

- Maximum 8 kW power requirement

- Ability to control manually in cases of power failure

- Total Width: 2,600 mm with legs retracted; 4,000 mm with legs deployed

- Sideways deployment: 750 mm

- Vertical deployment: 1,200 mm

- Weight per outrigger: 450 kg